Exploring Aluminum Dip Brazing vs Welding

When working with aluminum, choosing the right joining method can significantly impact the quality and efficiency of the final product. Aluminum dip brazing and welding are two popular techniques, each with its advantages and limitations. Understanding these can help in selecting the appropriate method for your specific application when using a local aluminum dip brazing or welding company. In this post, we will explore the differences between aluminum dip brazing and welding, and how they can set the stage for innovation in modern industries.

Assessing Aluminum Dip Brazing

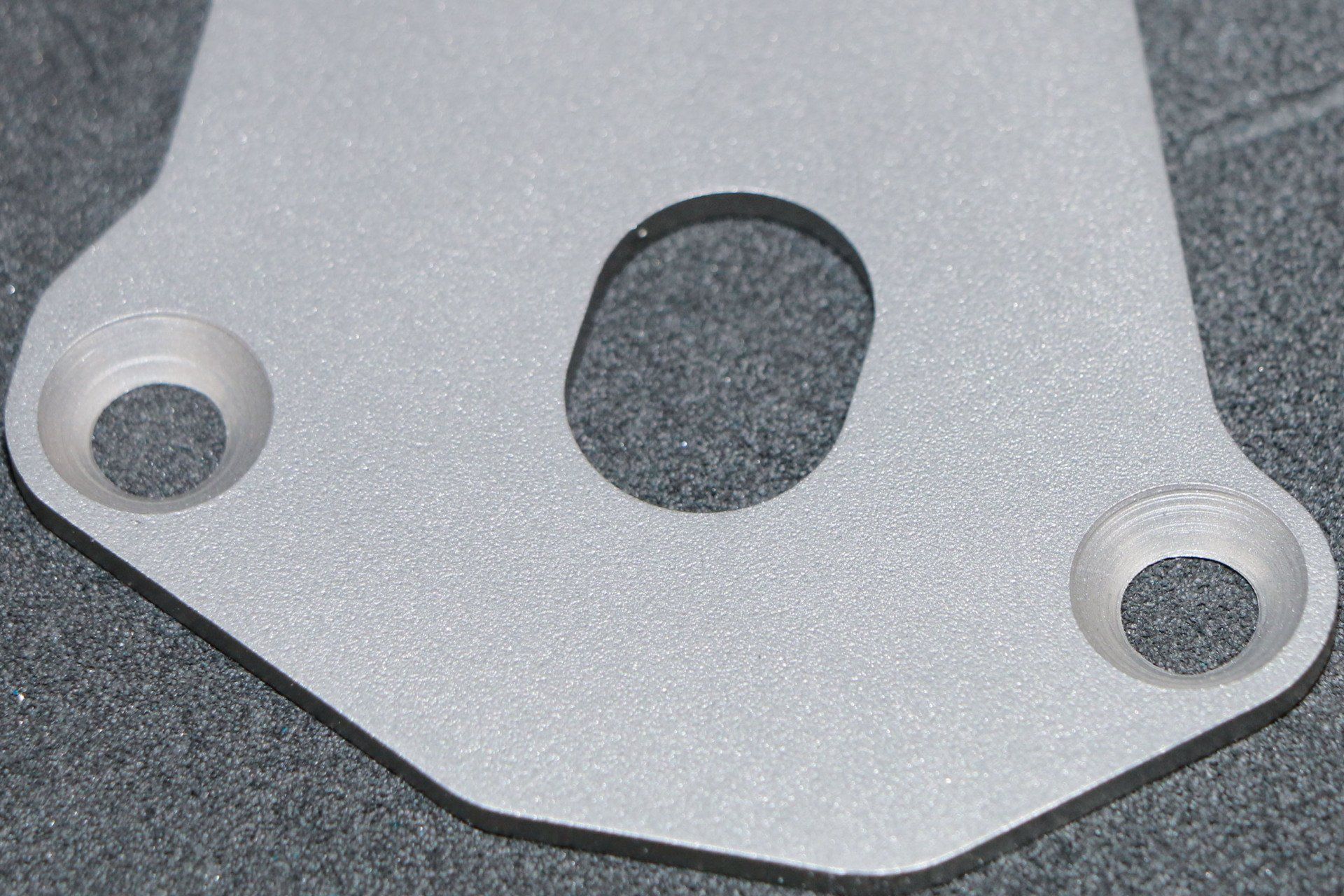

Aluminum dip brazing is a preferred method for creating leak-proof joints in complex assemblies. It involves immersing aluminum components and a brazing compound in a heated salt bath, allowing for uniform heating and bonding. This method is particularly beneficial for intricate or multi-joint assemblies, where precision and strength are paramount. Because dip brazing allows for multiple joints to be created simultaneously, it is often more efficient for producing complex structures compared to welding.

Analyzing Welding

On the other hand, welding provides superior strength for joints subjected to high mechanical stress. This is especially true for applications involving heavy-duty industrial use or structural components in construction and transportation. However, welding aluminum can be challenging due to its high thermal conductivity and the formation of an oxide layer, which can inhibit the process. Proper skills and equipment are vital to overcome these challenges, ensuring a strong and durable joint.

Comparing Sustainable Efforts

In terms of sustainability, aluminum proves to be a remarkably recyclable material—about 75% of all aluminum ever made is still in use, thanks to recycling, according to the Aluminum Association. Both dip brazing and welding techniques aim to harness aluminum's capabilities while enabling efficient reuse. With dip brazing offering less material waste and welding providing robust longevity, choosing the right technique also engages the environmental aspect of manufacturing, allowing recycled aluminum to continually find new life in innovative applications.

The choice between aluminum dip brazing and welding depends largely on the specific requirements of the project at hand. Whether prioritizing the complexity and precision of dip brazing or the strength and durability of welding, understanding both methods allows manufacturers to make informed decisions. By considering factors such as project design, material requirements, and sustainability, businesses can effectively leverage aluminum's potential to enhance their products while contributing to a cycle of resource conservation and innovation. If you have a project that could use the help of a local aluminum dip brazing company, contact Hi-Temp Brazing, Inc today!

Share On: