5 Things You Didn't Know About Metal Fabrication

Fabricating metal supports industrial output around the globe. According to Brandon Gaille, the world's metal fabrication industry should top $21 billion in 2024. Shaping, forming, and connecting metal pieces takes a lot of skill and experience to do it right. Here's a closer look at five things you likely didn't know about metal fabrication.

1. Metal Fabrication Has Several Steps

There is no one simple step to metal fabrication, such as stamping out a metal piece with an industrial stamping machine. Instead, each piece must be cut, formed, and machined to obtain the right shape. Then it might need to be welded or maybe riveted to another metal object to create something even bigger and more useful.

2. Secondary Treatments Are Required

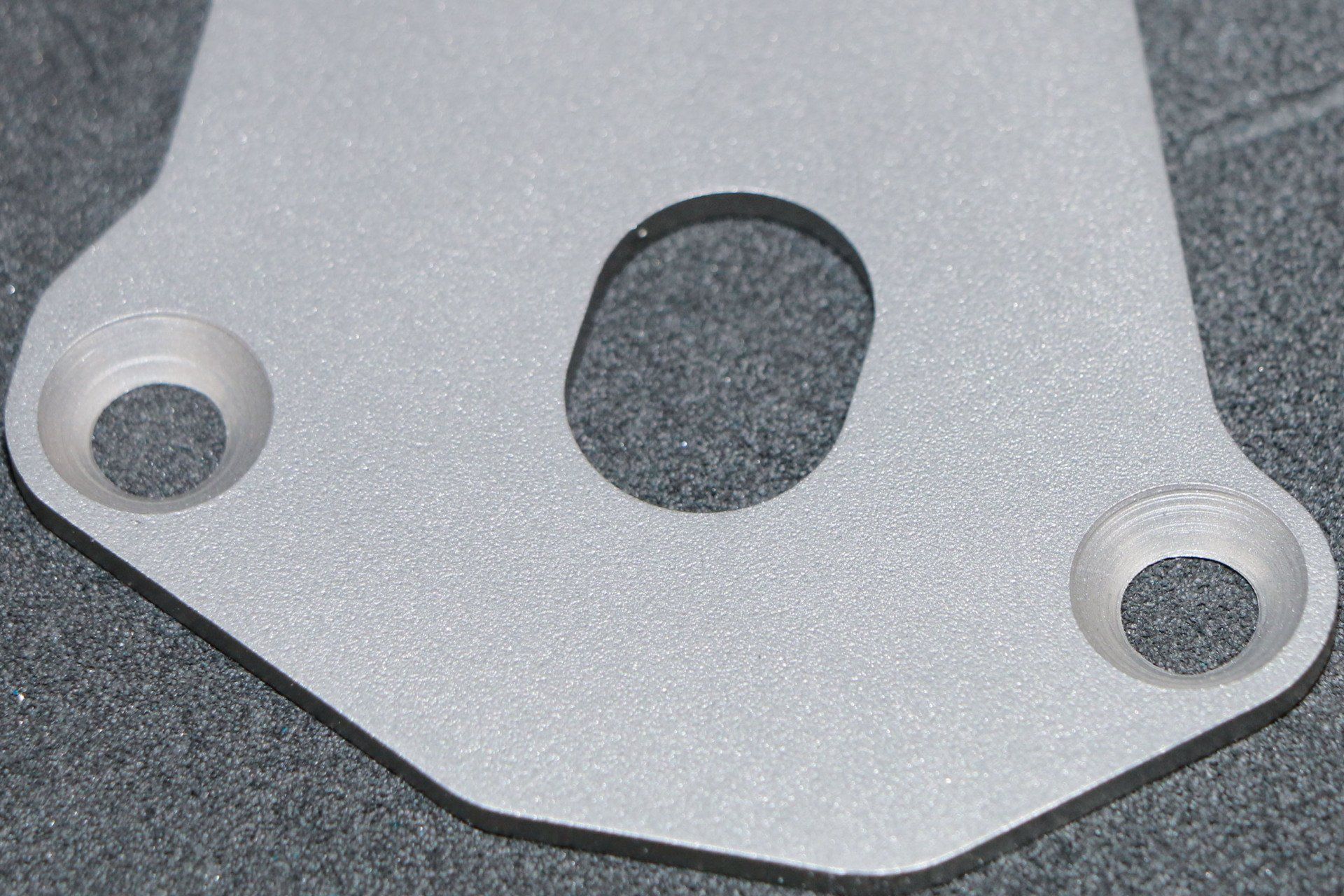

Once a piece of metal is shaped, formed, and smoothed out, it often still needs work. A secondary treatment might galvanize the metal piece, remove any burrs, or sandblast it to accept paint or another substance. Many pieces also undergo anodizing, plating, and final finishing to make them look good.

3. Many Types of Equipment Are Used

The many different processes of metal fabrication require many different types of tools and equipment. A lathe, grinder, or table saw might be needed to shape the raw metal. A press brake, roll forming, or a CNC machine might have to shape or remove metal to create the ideal piece. Many other methods and equipment also are needed to produce the best work.

4. Different Metals React Differently

Steel commonly is used in

metal fabrication, but so are many other types of metal. From aluminum to zinc, metal fabricating uses a variety of metals to produce different objects and pieces. Those metals all have different properties and different best uses. A skilled metal worker can help to determine which type of metal should be used for various pieces based on the overall design.

5. Metal Fabrication Has Limits

A piece of metal can be made into just about anything. Unfortunately, equipment and worker skillsets typically limit what metal fabrication can accomplish and so do the types of metal used. Advanced planning can help to ensure that the task is a viable one.

You can learn more about metal fabrication services if you call or visit us at Hi-Temp Brazing, Inc. We can review your diagrams and give you an accurate estimate of the cost.

Share On: